The light bent in an optical fibre laser is by refraction. An optical fiber cable passes the light via an impurity-free transparent silicon glass core. The core is covered by cladding, which is another layer made of silica with added materials to lower its refractiveindex. Due to the different refractive indexes of the core and cladding, the light will be reflected at the core-clad interface.

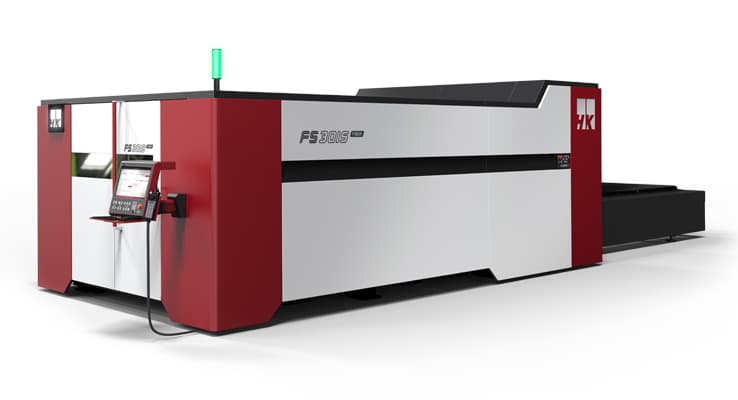

Designed by Mitsubishi engineers and built with Mitsubishi components, the GX-F Series is one of the only laser systems in the industry with a single source for service and support.